During surface inspection, embedded vision systems measure quality and deviations in material properties, as well as recognizing scratches, cracks, roughness and color changes. This inspection can be performed in a fully automatic process without impairing processing speed or productivity.

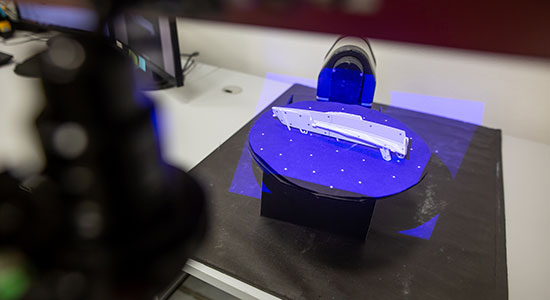

Imaging systems that combine 2D and 3D image acquisition are especially efficient. For example, the surface condition can be examined through a gray zone analysis in 2D, while the contour accuracy of the entire workpiece is measured using 3D laser triangulation – all in a single work step.

Furthermore, to enable the simple integration of the Photonfocus sensors in production plants or the realization of standalone solutions, the image data can be interpreted directly onboard.

All embedded vision systems from Photonfocus are designed for use in industry. They stand out from the competition thanks to their compact design and their high robustness and durability.

We will be happy to discuss any further requirements with you personally.

Just get in touch.

Are you looking for the right contact in a specific region? find out if contact details for your region are available. |