Wheels and tires are subjected to high stresses, strong temperature fluctuations and environmental influences. Damage or heavy wear endangers passengers and also has an impact on driving comfort.

Test systems with embedded imaging recognize deviations in the manufacturing process and test the quality of wheels and tires for registration and inspections, as well as during operation. To this end, the sensors and all-in-one solutions from Photonfocus are the perfect choice as stationary measuring systems and in mobile applications.

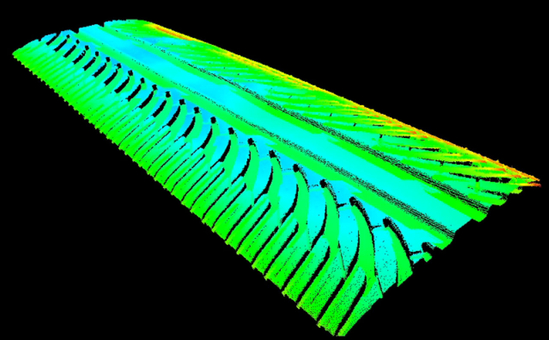

Laser triangulation is used for fast 3D measurement and inspection: A laser line is projected onto the workpiece to be inspected, while a camera is used to record the height offset of the line in pixels. If complete objects are scanned using this process, the individual light sections can be joined together to form a three-dimensional measurement result.

Photonfocus 3D sensors and intelligent embedded vision solutions with onboard data processing are ideally suited to measuring wheels, tires and profiles. They combine fast image sensors with subpixel-accurate calculations of the laser line positions in real time, thereby achieving extremely high triangulation rates. As a result, robust and economical inspection systems can be achieved with one or multiple cameras.

We will be happy to discuss any further requirements with you personally.

Just get in touch.

Are you looking for the right contact in a specific region? find out if contact details for your region are available. |