Automatic inspection systems detect the shape, color and quality of foods during production. Changes and deviations are recognized quickly and the quality of the goods is ensured prior to sale or further processing.

by the courtesy of 3Control

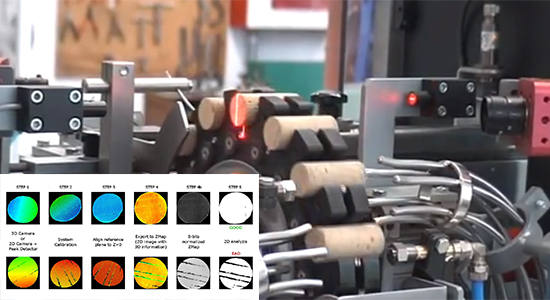

Quality and aesthetics also play a large role in the production of corks: 3Control Industrial Automation relies on Photonfocus embedded vision systems for integration in its plants, using them to monitor quality in cork production all over Europe. The 3D sensors analyze the color and shape of the blank corks, as well as pore size and possible damage. Based on their quality, the corks are divided into six classes. The devices can inspect up to 25,000 blank corks per hour.

Embedded vision systems from Photonfocus work with maximum image quality and speed. They have a modular structure and can also process data locally and onboard, making them perfect for integration into production lines or for standalone all-in-one solutions.

We will be happy to discuss any further requirements with you personally.

Just get in touch.

Are you looking for the right contact in a specific region? find out if contact details for your region are available. |