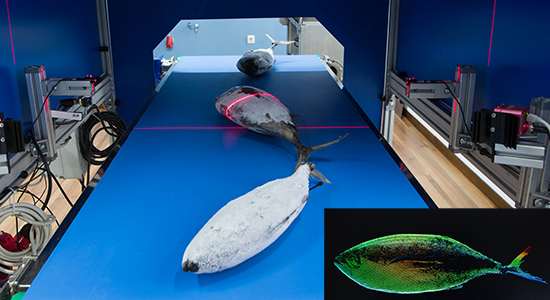

Fully automated systems for classifying and sorting enable a high level of productivity and economic efficiency in food production. This is where embedded vision systems come in: They can differentiate at high speed between sizes and shapes, as well as different types and quality levels. Depending on the application, the inspection systems work with 2D or 3D images and use laser triangulation to determine volume and weight. They then use this information to define packaging units or the optimum packing density in transport containers.

by the courtesy of Marexi

Capturing 2D/3D images and image data in the infrared spectrum (SWIR) delivers the best results. This enables colors and shapes to be assessed together and with pixel-precise accuracy. A further advantage of SWIR images is that analyzing the infrared spectrum allows the identification of impurities, spores or initial stages of decay that are invisible (or almost invisible) to the naked eye.

Embedded vision systems from Photonfocus stand out thanks to maximum resolution and processing speeds, robust quality and the option of processing data onboard.

We will be happy to discuss any further requirements with you personally.

Just get in touch.

Are you looking for the right contact in a specific region? find out if contact details for your region are available. |